HEMP NATURAL FIBER

Hemp natural fiber is a variety of the Cannabis sativa plant and is grown specifically for the industrial uses of its derived products and is also called Industrial Hemp. It can be refined into a variety of commercial items including paper, textiles, clothing, biodegradable plastics, paint, insulation biofuel, food, animal feed, etc

DIFFERENCE BETWEEN INDUSTRIAL HEMP AND CANNABIS AS A DRUG

Both industrial hemp and cannabis as a drug are derived from the species Cannabis sativa. They both also contain the psychoactive tetrahydrocannabinol (THC), but they are distinct strains of the species. Industrial hemp has lower concentrations of THC and higher concentrations of cannabidiol (CBD), which decreases or eliminates its psychoactive effects.

The legality issues involved with industrial hemp vary

widely between countries, depending on the different drug laws of these countries. Some

governments closely regulate the concentration of THC and will only permit hemp

bred with a certain low percentage of THC. Typically, hemp for industrial uses

contains below 0.3% THC, while Cannabis grown for medicinal or recreational use

can contain anywhere from 2% to over 20%. The fear that the growing of hemp

will make it more difficult to control the use of the drug variety is still

prevalent even though laws are gradually changing over time.

INDUSTRIAL HEMP

Hemp is probably one of the earliest plants to be cultivated. Hemp use archaeologically dates back to as far as the Neolithic Age in China around 12,000 years ago. The first identified coarse paper made from hemp goes back to the early Western Han Dynasty.

In Western Europe, the cultivation of hemp was not legally banned until the 1930s, but the commercial cultivation had stopped by then, due to decreased demand for and competition from increasingly popular artificial fibers.

In Japan, hemp was historically used as paper and as a fiber crop. In 1948, Marijuana was restricted as a narcotic drug in Japan even though it was never widely used there before. Hemp growers whose crop is used to make robes for Buddhist monks and loincloths for Sumo wrestlers were exempted.

Hemp is considered the strongest natural fiber in the world and is one of the fastest growing plants. In the U.S., George Washington and many other presidents cultivated hemp for rope. Levi Strauss patented his trouser jeans in 1873 from the indestructible sailcloth made from hemp!

HEMP PLANT PARTS

BAST

Hemp natural fiber is called bast and is one of the most valuable parts of the hemp plant. The bast are the fibers which grow on the outside of the plant stalk. It is these fibers that give the plants strength.

There are different processes to remove the fiber from the stem. Depending on which process is used, the hemp may be creamy white, brown, gray, black or green. The hemp plant produces a high fiber yield per acre. It can produce 250% more fiber than cotton and 600% more fiber than flax with the same amount of land.

When grown as a fiber crop, hemp grows to a height of 6-15 feet and up to .75 inches in diameter without branching. To help ensure the plant grows straight, it is densely planted (as many as 300 plants per square yard).

Hemp fiber has been used for centuries for the manufacture of industrial materials. It was commonly used to make sail canvas. In fact, the word ‘canvas’ is derived from the word ‘cannabis.’

Hemp fiber, when mixed with fiberglass, flax, and kenaf (a fiber plant native to east-central Africa), can be used to make composite panels for automobiles, including Audi, BMW, Ford, GM, Chrysler, Honda, etc. For apparel and furnishings, the fibers can be 100% hemp, though it is usually blended with other fibers including flax, cotton or silk, etc.

HURDS or SHIVES

The hurds or shives are the woody inner parts of core of the hemp stem. These are broken into fragments and separated from the fiber. These parts are typically used for animal bedding or litter or for horticultural mulch.

HEMP SEEDSHemp seeds can be used in many ways. They can be eaten raw, ground into hemp meal, sprouted, or made into dried sprout powder. They can also be made into a liquid and used for baking or for beverages such as hemp milk and tea.

Hemp seeds are important as a complete source of protein because they contain all the essential amino acids. The seeds are also exceptionally rich in 2 essential fatty acids – Omega-6 and Omega-3 in a healthy optimal ratio of 3 to 1 (6 to 3). They have been shown to benefit skin diseases and provide relief from eczema.

Hemp seeds are actually more nutritious and more economical to produce than soybeans and the protein in hemp seeds can be used to produce just about any product made from soybeans, such as tofu, veggie burgers, etc. It is also more digestible than soybeans and it does not have to be cooked or fermented first.

The seeds are also a great source of vitamin E and B vtamins and minerals such as phosphorus, potassium, sodium, magnesium, sulfur, calcium, iron, and zinc. They are also a great source of arginine and gamma-linolenic acid (GLA) which have been linked to reduced risk of heart disease. The high levels of GLA may reduce symptoms associated with PMS and menopause as well.

Whole hemp seeds contain high amounts of both soluble and insoluble fiber, which benefits digestive health. However, dehulled or shelled hemp seeds contain very little fiber.

HEMP OIL

Hemp oil is cold-pressed from the hemp seed and is high in unsaturated fatty acids.

HEMP LEAVES

The leaves of the hemp plant are not as nutritional as the seeds but are edible and can be consumed raw in salads or pressed to make juice. In the US, hemp can be imported to be used legally in food products.

HEMP CULTIVATION

CLIMATE

The best climates for growing hemp are warm tropical zones or moderately cool and temperate climates. In the northern hemisphere, hemp is usually planted between March and May and in the southern hemisphere between September and November. The plant matures in about 3 to 4 months.

Hemp plants shed their leaves throughout the growing season. This not only adds rich organic matter to the topsoil but also helps it retain moisture allowing hemp to be more drought-resistant.

Hemp is very self-compatible so it can be grown several years in a row in the same fields. It also benefits crops grown after it. Therefore it is generally grown before winter cereals.

Its advantages are high weed suppression, soil loosening by the large hemp root system, and the positive effect on the physical condition of the soil. Hemp’s strong roots could penetrate for 3 feet or more underground. The roots anchor and protect the soil from runoff. They build and preserve topsoil and subsoil structures similar to those of forests.

SOILS

Hemp grows best on a loose, well-aerated loam soil with high fertility and abundant organic matter. Poorly-drained clay or poorly structured soils won’t work because seedlings and young plants are prone to damping off. Sandy soils with adequate irrigation and fertilization will also work but these additional costs often make production uneconomical.

MALE AND FEMALE PLANTS

Hemp is dioecious, meaning the plants can be either male or female. However, there are big differences between male and female plants in growth rate and development. Since the male plants tend to flower and die earlier than the female, the hemp plants are often bred to be monoecious in order to minimize the impact of this on production. The result is plants that are mostly females with a small percentage of male plants included for pollination.

DISEASES

Hemp plants can be vulnerable to bacteria, fungi, nematodes, viruses, and other miscellaneous pathogens. This can often lead to reduced fiber quality, stunted growth, and the death of the plant. However, these diseases rarely are able to affect the yield of a hemp field, so hemp production is not traditionally dependent on the use of pesticides.

HEMP PROCESSING

Separation of the core hurd and bast fiber is called decortication. It is usually water-retted or cured first and then the fibers are beaten off the inner hurd by hand in a process known as scotching.

After the Marijuana Tax Act of 1937, although mechanical technology was available at the time, the technology for separating the fibers from the core were stalled. In 1997, Ireland and parts of the British Commonwealth as well as some other countries began to legally grow industrial hemp again and the technology started to evolve.

China uses chemical methods to process hemp while producers in Europe have begun using cleaner biologically-based enzyme technology. This improved technology with microorganisms or enzymes could augment or replace traditional water retting. Steam explosion is another potential technology that has been experimentally applied to hemp.

Unfortunately, neither of the above methods produces fabric with the same whiteness and softness as cotton. Thus, hemp clothing is often blended in Canada, an innovative enzyme process was invented to transform industrial hemp into a soft , white ‘canadian cotton’ product called Crailar.

USES FOR HEMP NATURAL FIBER

There are a multitude of uses for hemp, both industrially and medically. The legal issues over the years have made some products uneconomical for the average consumer. As hemp production technology improves and legal issues are resolved, hemp production may prove to once again be a useful and profitable business.

Below are some of the more well-known uses:

BIODIESEL FUEL

Biodiesel fuel can be made from the oils in hemp seeds and stalks and this is sometimes called ‘hempoline.’ Alcohol fuels (ethanol and methanol) can be made by fermenting the whole plant.

The production of vehicle fuel from hemp is currently small. Commercial biodiesel is typically produced from other materials such as cereals, coconuts, dead plant and animal material, kitchen waste, etc., which are much cheaper raw materials.

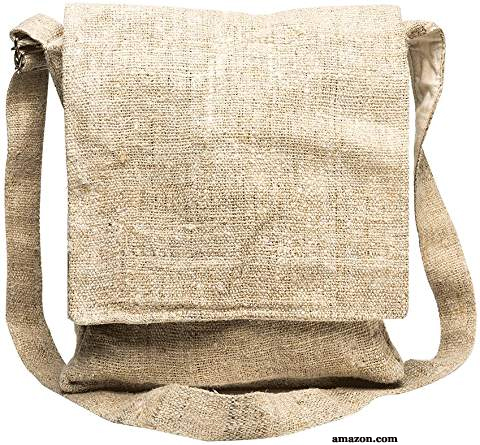

HEMP NATURAL FIBER CLOTHING

Hemp fiber creates one of the most eco-friendly fabrics in the world. (This is raw hemp fiber, not viscose or rayon made of hemp.)

Hemp fiber is a bast fiber, similar to flax (linen), extracted from the stalk of the plant.

The hemp plant:

- Requires little or no pesticides.

- Crowds out weeds without

herbicides.

- Needs only moderate amounts of fertilizer.

- Is frost tolerant.

- Requires

only moderate amounts of water.

- Grows in all 50 states.

- Also controls erosion of the topsoil. Produces oxygen.

- It is a renewable resource that can be cultivated in as little as 100 days.

NOTE: Always read the tags on ‘hemp’ clothing to determine whether or not the item is 100% hemp fiber or a blend with other natural or synthetic fibers.

ADVANTAGES OF HEMP NATURAL FIBER CLOTHING

- Tensile strength is 8 times that of cotton fiber.

- Extremely durable

- Eco-friendly

- Hypo-allergenic (though no more so than any other plant fiber, such as cotton , linen, ramie, etc.).

- May be able to kill staph and other bacteria

that might come in contact with its surface (though this has not yet actually been proven).

- Will soften with age and with each washing.

- Breathes well so great for hot weather. It resists mildew and absorbs moisture.

- Highly absorbent.

- UV resistant.

DISADVANTAGES OF HEMP NATURAL FIBER CLOTHING

- Not colorfast so the color is often not rich.

- Like linen, hemp wrinkles easily.

- Is a little bit stiff.

- Look for hemp blended with other fabrics to make it feel softer.

HOW TO CLEAN HEMP FABRIC

- Use either cold hot water.

- Bleach is fine to use.

- Wash dark colors separately.

- Allow to air dry. Using a dryer can cause

wrinkles and make it shrink, though it can be dried on a low temperature and removed promptly.

- Wrinkles cannot be removed from hemp by hanging it up to dry. It would require ironing at high temperatures.

- Can be dry cleaned.

HEMP NATURAL FIBER IN CONSTRUCTION MATERIALS

Hemp fibers are extremely strong and durable and are usable as replacement for wood for many different jobs. The building of what are known as Renewable Homes is one such project. The first US home made of hemp-based materials was completed in 2010 in North Carolina.

Concrete-like blocks made with hemp and lime are used as insulating material for construction. These concrete-like blocks are called Hempcrete. The thermal properties of hempcrete, its low cost and ease of use, along with the ability of hemp building materials to trap CO2 (carbon dioxide) make their use very attractive from an atmospheric point of view.

The very high tensile strength of hemp can effectively reduce cracking of concrete.

MEDICINE

For medical conditions, hemp-derived cannabidiol (CBD) oil has been shown in limited scientific studies to alleviate symptoms. There is currently a movement to make CBD oil exempt from the Controlled Substances Act for those that live in states where it is illegal.

PAPER FROM HEMP NATURAL FIBER

The oldest piece of paper (over 2000 years old) was discovered in China and made from hemp. The Gutenberg bible of the 15th century and Lewis Carroll’s Alice in Wonderland of the 19th century were printed on hemp paper. Thomas Jefferson wrote the early drafts of the Declaration of Independence on hemp paper produced in Holland.

Hemp paper is made mostly from the pulp obtained from the fibers of industrial hemp. The pulp has 4 to 5 times longer fiber than wood pulp. It also has lower lignin, which is the glue that holds plants together such as hardwood fibers. The lower content of lignin means it can be pulped using fewer chemicals. It can also be bleached using a gentle hydrogen peroxide rather than toxic chlorine compounds and dioxins which are generated as a by-product of paper production. The hemp pulp has very high tear resistance and tensile strength as well.

Unfortunately, production costs are about 4 times higher than for paper from wood so hemp paper is not used for mass applications such as printing, writing, and packaging paper. At this time paper made from hemp pulp is used mainly for specialty papers such as cigarette paper, banknotes, and technical filter papers. However, with the emergence of 3D printing, hemp is the perfect composite plastic for an enormous number of industrial application where plastic is currently used.

The quality of hemp paper is far superior to tree-based paper. It will last hundreds of years without degrading and can be recycled many more times than tree-based paper.

ROPE FROM HEMP NATURAL FIBER

Hemp rope was used for centuries for sailing ships. However, hemp rope can break from rot since the fibers tend to hold liquid at the interior while seeming dry from the outside. Thus, the rope had to be protected by tarring. Hemp rope was eventually replaced by manila rope (sometimes referred to as Manila Hemp because it does not need tarring. Manilla hemp is actually abaca, a species of banana. Some people prefer hemp rope’s coarser texture because the rope can bind against itself for better knot stability.

Hemp natural fiber twine used for gardening and landscaping is very useful because hemp is round by nature making the twine easy to work with. It is also fully biodegradable.

Hemp jewelry is made from a combination of knotting hemp twine (macramé) combined with beads. The hemp twine varies in thickness and comes in a variety of colors. The twine used for crafting projects makes attractive and firm knots.

WATER AND SOIL PURIFICATION

Hemp can clear impurities and unwanted substances or chemicals out of wastewater. Through a process known as phytoremediation, hemp can also clear radioisotopes and a variety of other toxins from the soil, water, and air, especially around nuclear sites such as the Chernobyl nuclear disaster site.

HEMP FOR WEED CONTROL

The tall, thick foliage of the hemp plants, which can be planted very densely will smother and kill tough weeds. Thus farmers can avoid the use of herbicides and gain organic certification. On the other hand, since the plant grows so rapidly and densely, some governments consider hemp a weed and it is prohibited.

WORLD PRODUCERS OF HEMP

China produces more than 70% of the world output of hemp natural fiber.

France does about a quarter of the world production. In France, a large proportion of industrial hemp is used for cigarette papers and technical applications. A small portion is used in the automotive sector. The hurds are used mostly for animal bedding.

Smaller production occurs in the rest of Europe, Chile, and North Korea.

Actually, over 30 countries produce industrial hemp.

The United Kingdom and Germany resumed commercial production of hemp natural fiber in the 1990s. In the UK, it is mostly used as bedding for horses.

Canada, the UK, the US, and Germany process hemp seed into food products and cosmetics. Many traditional growing countries still continue to produce textile-grade fiber.

The North American market of hemp natural fiber is still in its infancy since Canada just legalized hemp production and sale in 1998. In Canada, hemp is cultivated mostly for its food value as hulled hemp seeds, hemp oils, and hemp protein powders, with a small fraction used for construction and insulation.

A Canadian technology plant has recently developed a process for producing hemp natural fiber that is cleaner, long, coarser, and stronger. The hemp fiber from this technology plant has already been used to build skateboard parks in Canada and was also used by Beijing to construct the bobsled and luge tracks for the 2022 Winter Olympics.

The Soviet Union was the world’s largest producer of hemp from the 1950s to the 1980s. Ukraine has been one of the world’s largest centers for developing new hemp varieties, focusing on improving fiber quality and low THC content and per hectare yields. Unfortunately, after the collapse of the Soviet Union, the commercial cultivation of hemp declined sharply.

HEMP NATURAL FIBER PRODUCTION IN

THE UNITED STATES

bIn 1937 the Marijuana Tax Act passed in the US levied a tax

on anyone who dealt commercially in cannabis, hemp, or marijuana. The passing

of this act to destroy the US hemp industry was thought to involve businessmen

Andrew Mellow, Randolph Hearst, and the DuPont family trying to protect their investment interests.This notion was disputed by historians.

Actually, it makes more sense that hemp/cannabis prohibition was fueled by racism, fear of crime, and culture wars.

Surprisingly, hemp natural fiber was actually used extensively by the United States during WWII to make uniforms, canvas, and rope. It was considered as a necessary crop to win the war. In the US, hemp cultivation was legally prohibited, but during WWII, farmers were encouraged to grow hemp for cordage to replace Manila hemp previously obtained from Japanese-controlled areas.

Hemp natural fiber was made illegal to grow without a permit in the US under the Controlled Substances Act passed in 1970 because of its relation to marijuana. Any imported hemp products must meet a zero tolerance level.

The Agricultural Act of 2014 allowed colleges and state agencies to grow and conduct research on hemp natural fiber in states where it is legal. Hemp businesses and startups have usually had difficulty marketing and selling non-psychoactive hemp products and some online advertising platforms and financial institutions do not distinguish between hemp and marijuana.

The Hemp Farming Act of 2018, which was part of the 2018 Farm Bill signed by President Donald Trump on December 20, 2018, changed hemp from a controlled substance to an agricultural commodity, legalizing hemp federally. Now it is easier for farmers to get production licenses, get loans to grow hemp natural fiber and also allow them to get federal crop insurance.

It is important to understand the 2018 Farm

bill legalizes industrial hemp. However, people cannot grow it as freely as they can grow

any other crop. The currently accepted legal definition of industrial hemp is any part of the cannabis plant that has no more than 0.3 percent of THC on a dry weight basis.

THE FUTURE OF

HEMP NATURAL FIBER IN

THE UNITED STATES

In the United States, the public’s perception of hemp natural fiber as marijuana has blocked hemp from becoming a useful crop and product. One major problem that has been at the core is hemp resembles crude marijuana and there is no visual way to distinguish the two.

Critics of the legalization of hemp feared it would make enforcement of the marijuana laws by federal and state authorities extremely difficult. Proponents of the legalization of hemp sometimes charged ulterior motives such as protection of the synthetic fiber, wood pulp, petrochemical and pharmochemical industries.

The future of hemp natural fiber in the United States will require research and infrastructure. New mechanized options for harvesting and decorticating (removing the fiber from the center of the stalk will be needed. These machines in the future will likely resemble all the other agriculutural equipment on the farm. However, it takes demand for larger companies to invest in the research to develop these machines, as well as farmers doing field research to figure out the methods and equipment needed for efficiency.

Hemp will be a highly regulated crop for both personal and

industrial production. Hemp natural fiber used for medicinal purposes is

still under the Controlled Substances Act and this includes CBD oil,

which is currently becoming a sought-after hemp product. The 2018 Farm

Bill will make available more legal CBD products but not all CBD

products will be available legally in all states in the immediate

future. We have made much progress with the latest Farm Bill. It will be interesting to see where the hemp natural fiber industry goes from here.

"The Cleanest Clean You've Ever Seen."

by

ABC Oriental Rug & Carpet Cleaning Co.

130 Cecil Malone Drive Ithaca, NY 14850

607-272-1566

As of October 1, 2018, we have joined with One Tree Planted.org to help with sustainability and reforestation on our planet by planting trees!

For more information on One Tree Planted.org, please see our article.

Our Press Release can be reached below:

Cleaning Company Announces Partnership with One Tree Planted.org

ABC

Carpet & Rug

Spotting Guide

ABC

Carpet & Rug

Spotting Guide

Learn how to remove spots with ordinary household solutions

Sign up below to gain access to your complementary Spotting Guide from ABC.

Registering your email address guarantees you will be notified whenever discount savings coupons become available.

Did you know that our ABC Responsible Care Spotter can get those pesky spots out of your carpet and rugs and will work equally as well on your clothes and upholstery?

Stop by our office and pick one up. They are $5.00 + Tax but if you have carpets or upholstery cleaned in your home or business, just request a free one from your Technician.

And don't forget to fill out the form above to download your free ABC Spotting Guide!

ABC Oriental Rug & Carpet Cleaning Co.

is a FOUNDING MEMBER of the

Association

of Rug Care Specialists.

"To Teach, Cultivate and Advance the Art and Science

of Rug Care"